Energy Star EV Charger Requirements

If we are to evolve how we fuel transport technology then the infrastructure that supports it must also be smart, sustainable and efficient in a bid not to undermine the green paradigm shift.

Energy star has been leading the way in setting energy efficiencies by establishing tougher recommendations for various power consuming equipment for many years. In an evolving market of new technologies that transition their way into commodity products for the mass market, Energy Star set efficiency benchmarks to benefit the consumer and the planet as a whole. As the roll out of electric vehicles is set to become the norm with many countries declaring the discontinuation of fossil fuel powered vehicles, the manufacture of chargers is set to boom. As such the chargers of the utopian future must in turn be energy efficient for the green revolution to be credible.

Please get in touch with your EVSE charger power conversion requirements:

Contact usEVSE - electric vehicle supply equipment (chargers) spend most of their time in standby mode with no vehicle connected (approximately 85% of the time), so Energy Star has focused on improving standby efficiencies as it did with external power supplies many years ago. Car chargers that carry the Energy Star label will use 40% less energy than their predecessors in standby and drives the new norm for the resource conscious EV driver. According to the EPA (Environmental Protection Agency), the Energy Star requirements could help save more than $17 million and more than 130 million kg of greenhouse gas emissions each year. Given that one of the main divers of switching to EVs is the environment this of course is very pertinent.

Currently level 1 (120VAC) and level 2 (240VAC) products <80A outside of the EV are covered by the Energy Star requirements. They have begun investigating improvements to DC fast chargers up to 350KW and one day wireless chargers, but currently the focus is on the lower power AC chargers. Further to this Energy Star highlight smart chargers that utilise grid power or onsite renewable power at preferential times also play a crucial part in efficient energy usage and saving the user money.

Displays play an important part in the EVSE’s functionality and energy consumption. ABC (automatic brightness control), adapted from Energy Star’s test method for displays and televisions, play a role in not only usability and energy conservation but also reducing light pollution from the charging stations at night.

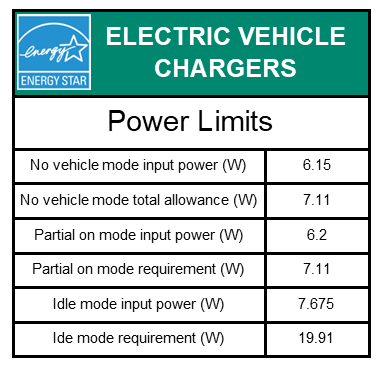

Limits have been set for the various charging modes; ‘No vehicle’ mode, ‘Partial on’ mode and ‘Idle mode’.

1) Disconnected: Condition of the equipment during which all connections to power sources supplying the equipment are removed or galvanically isolated and no functions depending on those power sources are provided. The term power source includes power sources external and internal to the equipment.

2) No Vehicle Mode: Condition during which the equipment is connected to external power and the product is physically disconnected from vehicle (mode can only be entered or exited through manual intervention). ‘No Vehicle Mode’ is intended to be the lowest-power mode of the EVSE.

3) On Mode: Condition during which the equipment provides the primary function or can promptly provide the primary function.

- a) Operation Mode: Condition during which the equipment is performing the primary function, where the vehicle is connected and accepting energy.

- b) Idle Mode: Condition during which the equipment can promptly provide the primary function but is not doing so.

4) Partial On Mode: Condition during which the equipment provides at least one secondary function but no primary function.

Further information can be found at Energy Star

FiDUS Power can help you with your IEC 61851 compliant energy efficient EV charger design, offering power conversion application solutions:

- Charge pilot +/-12V Oscillator supply for negotiating charge rate

- IGBT/SiC/GaN driver (+15V/-4V) to control 3ph high power switches

- LED back light driver for displays

- RS232/RS485/CAN/wifi/GPRS/Ethernet for communication integration and isolation

- MCU 3.3V/5V to power the micro controller

- Point of load (POL) converters for ancillaries

- Signal isolators

- High accuracy current transducers for precise power measurements and fault detection.

- In-cable control and protection device (IC-CPD)

- 100-3000V input DC-DC converters for connection to DC bus of fast chargers to generate 12V low voltage DC bus without 3ph to 1ph transformer.

- Rugged AC-DC converters; salt spray tested, conformal coated and 85-305VAC input for direct connection to 3ph + Neutral connection.

EVSE’s are installed on sites that can face hostile conditions; voltage fluctuations from local harmonics and transients, sitting in direct sunlight and being installed in isolated locations push the limits of thermal performances of power supplies. This in combination with exposure to humid and corrosive seaside air the life and operation of most common power supplies on the market would be limited. Our offering of energy efficient power converters with; wide temperature of operation (with guaranteed start up and longevity), conformal coating, surge protection and extra wide AC input make them the logical choice for the EV charger designer.